Hwashi IBC Cage Automatic Production Machine with 12 Months Warranty

AI-Powered Quality Assurance and Real-Time Monitoring

The Hwashi IBC Cage Automatic Production Machine represents the pinnacle of manufacturing innovation, combining advanced automation technology with precision engineering to deliver a complete solution for Intermediate Bulk Container (IBC) cage production. This state-of-the-art system transforms raw materials into high-quality IBC cages through a fully integrated, automated process that ensures exceptional quality, maximum efficiency, and significant cost savings.

Advanced Features & Technology

Fully Automated Production Line

- Integrated system combining automatic welding, mesh unloading, bending, locking, hole making, and punching processes

- Requires only 3-4 operators

- 24/7 continuous operation capability

- 80 cages per hour production rate

Precision Engineering

- Multiple welding heads operating simultaneously with CNC technology for exceptional accuracy and consistency

- 6-7 welding heads for uniform results

- ±0.1mm dimensional accuracy

- 60 seconds per cage cycle time

AI-Powered Quality Assurance

- Intelligent defect detection system that identifies and corrects production anomalies in real-time

- Automated parameter adjustment

- Real-time monitoring and analytics

- Consistent quality control

Main Weld Frame

Four sets of MF transformers regulate six sets of welding electrodes, ensuring optimal welding quality for each welding point. The bilateral piano-style welding technique expedites the welding process significantly. Each metallic grid mesh can be completed within one minute.

The design incorporates upper and lower air cylinders to guarantee a flat welding position. Additionally, the welding electrodes feature a screw design, enhancing durability with each use.

Six-Head IBC Frame Automatic Welding Machine

The welding power system features four sets of advanced MF DC power sources, enabling simultaneous welding at six different spots. A dual-layer fixture feeder enhances operational efficiency - while one fixture is actively engaged in welding, the other can seamlessly load materials.

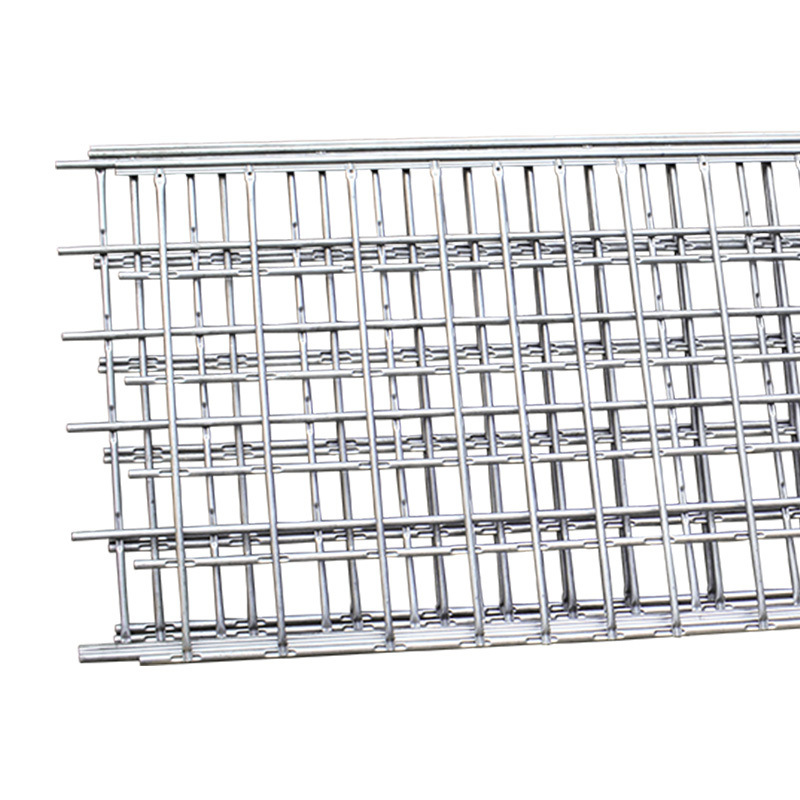

Flat Tube Mesh and Firm Welding Quality

The welding apparatus transforms tubes into a distinctive flat mesh configuration, ensuring welds of unparalleled strength and robust quality. The welding process is efficiently completed in approximately 60 seconds.

Vertical Double Station IBC Frame Bending Machine

The IBC cage frame dual-station bending machine guarantees high precision in bending, stable operations, and remarkable efficiency.

Bend the Flat Mesh into Square Shape

The bending machine transforms the flat mesh into a precisely squared frame in approximately 20-25 seconds.

Bending Beam

- CNC processed bending beam ensures precise bending angles

- Each mold on the bending beam can be adjusted upward and downward for about 3mm to increase bending range

- 120 degree mold design makes each bending angle more smooth

Bending Frame

The machine frame features a robust rectangle design with thicker steel columns and a door-shaped cover panel, ensuring exceptional firmness and stability.

Hydraulic Pressure Station

Specifically designed for bending pallet tank meshes, the IBC bending machine shapes them into rectangular frames with precise dimensions of (1200±5mm)*(1000±5mm).

IBC Cage Frame Locking Machine

Meticulously crafted as a cohesive unit, boasting exceptional precision in insertion, robust locking strength, and a seamless blend of stability and efficiency.

Locking Efficiency and Quality

- Adjustable clinching arm tailored to different IBC metallic cage designs

- Hydraulic and pneumatic design enhances machine efficiency

- Engineered for automatic joining of the two sides of the pipe

- Hydraulic clinching mold creates tight clinching spots to prevent cracking

- Hydraulic pressure station with auto-sending device ensures smooth production

IBC Cage Frame Hole Making and Punching Machine

Used to form holes on the frame so the complete frame can be fixed on the base frame. The hydraulic-powered process takes about 25-30 seconds to complete.

Hole Making Efficiency and Quality

- Pressing heads with pressing mold

- Hydraulic station

- Punching head locating panel

- Left-right, forward-backward adjustable panel for wider positioning range

IBC Cage Base Frame Welding Machine

The design adopts horizontal structure and 7 welding heads for completing the welding of base frame. The operator only needs to load and unload the product while the machine performs automatic welding.

Product Features

- Horizontal structure with 7 welding heads for base frame welding

- Automatic unloading of welded pallets

- 3 sets of MF DC 250KVA power for increased quality and production rate

- Solves problem of unstable welding quality caused by manual work

- Higher production rate and automation level

Technical Specifications

| Product Name |

IBC frame production line |

Style |

single row /double row |

| Max welding width |

1200mm |

Max welding length |

4250mm |

| Brand |

Hwashi |

Colour

| blue/yelllow/custom |

| Equipped Power |

350kVA/400kVA |

Place of Product

| Zhejiang Province,China |

| Voltage |

3p 380V |

Material

| Galvanized Pipe |

| Tickness of the pipe |

1-2mm |

duty cylce

| 20% |

| Diameter of the pipe |

14-20mm |

Frequency

| 50HZ/60HZ |

| pipe loading method |

manual/2 labors |

Cable size

| ≥70mm3 |

| working capacity |

350-450(480-550) pcs/8 hours |

air pipe size

| G1 |

| labor demand |

2-3 labors |

Water pipe size

| G1 1/4 |

Product Features - Tank Sending System

- Suitable for factories that separate the blowing machine workshop and the cage workshop

- Test tanks are transported by conveyor to the cage workshop with no human intervention required

- Includes IBC Bended, Clinching and Punched Cage Placement Area

- Welded Pallet Stocking Area

- Auto Pallet Assemble Path

- Pallet Welding

- Rotating Cage and Pallet Assemble Area Safe Passage

- Pallet Plate Stocking Area/Auto Feeding

Why Choose Hwashi?

- 20+ years of experience in welding and automation technology

- ISO 9001 certified and CE approved for international quality standards

- 24/7 technical support and comprehensive after-sales service

- Customizable solutions tailored to your specific production needs

- Industry 4.0 ready with IoT integration capabilities

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!