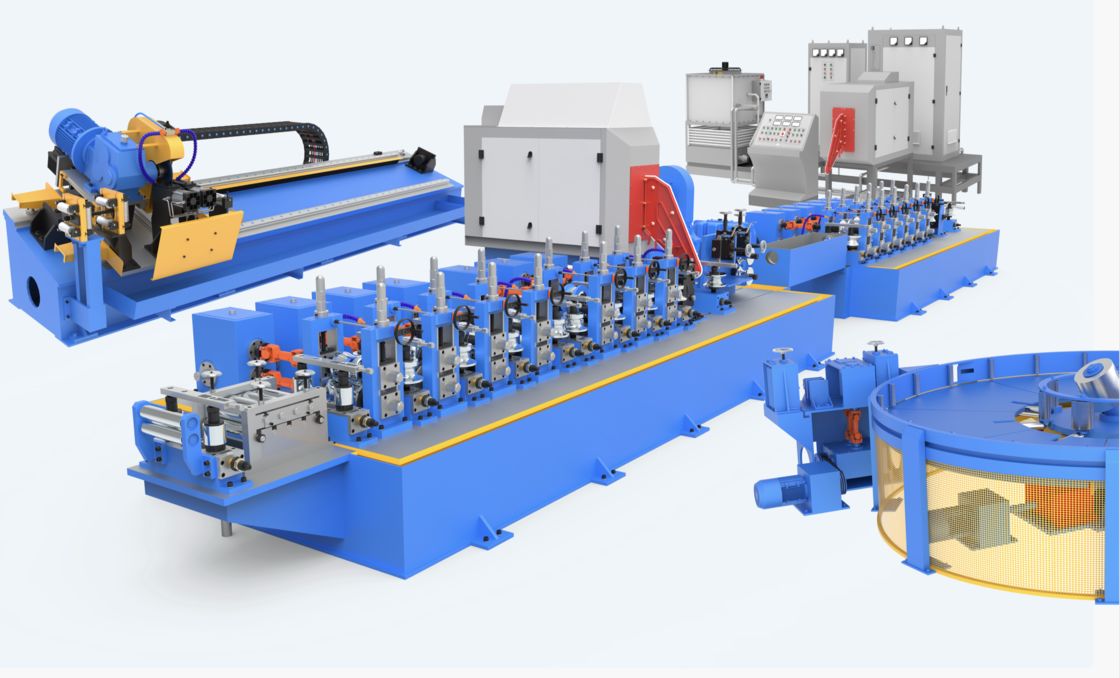

最先端の自動化によって 鉄筋ラック製造に革命を起こす

効率性,精度,スケーラビリティが 優位性を維持するための鍵です鉄筋の自動生産ライン高品質の基準を維持しながら 卓越した生産性を提供します 家用アイロニングラックを製造する場合でも商業用洗濯用ソリューション生産のあらゆる段階を効率化します. 原材料の加工から最終組み立てまで.

製造効率を再定義する

-

完全自動化 労働依存度最小化機械の腕,精密な輸送システム,インテリジェントセンサーを備えたこのラインは,切断,曲げ,溶接,表面処理労働コストを最大60%削減し 人間の誤りも最小限に抑えます

-

一貫した品質管理: 統合された視力検査システムとリアルタイムモニタリング技術により,各段階の寸法,溶接,表面仕上げの欠陥が検出され,すべての製品に均等な品質が保証されます.

-

柔軟なカスタマイズ: ラインは,迅速な切り替え能力を持つマルチモデル生産をサポートします. 簡単に異なる鉄筋ラックサイズ,形状,および材料種類 (ステンレス鋼,アルミニウム,HMI コントロールを直感的にできる.

技術仕様:信頼性のために構築

処理範囲: 60cm×40cmから120cm×80cm (より大きなモデルにカスタマイズできます) のアイリスニングラックサイズに対応します.

電源: 380V/50Hz 三相電源,省エネモードで運用コストを削減する.

物質的相容性: 高精度で金属シート (厚さ0.5~2mm) とチューブ (直径Φ10~Φ30mm) を扱う.

自動化レベル:PLC制御システム,タッチスクリーンインターフェース,モバイルまたはPCによる1クリック操作とリモートモニタリングを可能にします.

安全性: 緊急 停止 ボタン,保護 囲み, 過負荷 防護 操作 者 の 安全 と 機器 の 長寿 を 保証 する.

理想的な:

家庭用品メーカーが 生産を拡大しようとしている

製品の一貫性を向上させることを目指す洗濯機機器のサプライヤー

製造期間や労働コストを削減したい企業

自動化が精密さを満たす 鉄筋の生産の未来に投資する今日,カスタマイズされた引上げと技術的な相談のために私たちと連絡してください!

鉄筋の自動生産ラインは 高品質で効率的な製造を保証する 精密な工学プロセスの一連の統合ですその 基本 的 な 機能 は,先端 な 溶接 技術 に 基づい て い ます中間周波数ロール溶接が重要なステップとして機能し,一連の調整された段階によってサポートされます.

1.原材料の準備と切断

処理 は,金属 の コイル (ステンレス スチール,アルミニウム,炭素 スチール) を 巻き出し,精密 切断 機械 に 供給 する 自動 材料 処理 から 始まります.切断機は金属シートやチューブを正確な寸法 (0から) に切るこのステップは,原材料の均一性を確保し,一貫した下流加工の基礎を築く.

2折りたたみ 形成

切断後,金属部品はロボットの折りたたみステーションに転送されます.ここで,カスタム・マースを搭載した液圧プレスは,シートを鉄筋ラックの構造部品に形作ります.フレームなどロボットアームは,正確な角度制御 (容量 ±0.5°以内) と繰り返し性を確保し,組み立て中にすべての部品がシームレスにフィットすることを確保するために重要です.このステージは様々なデザインに適応しますシンプルな長方形の枠から 複雑な多重構造まで

3中周波ロール溶接

製造ラインの礎石として,中頻ロール溶接は,鉄筋ラック部品の優れた結合強さを提供します.このプロセスは,回転電極を通過した高周波電流 (400~600Hz) を使って連続的な電流を生成します.メタル部品のシームに沿った高整合性溶接,例えば,主枠に支柱棒を固定したり,折りたたむ接着を固定したりする.中間周波数ロール溶接は熱を減少させるまた,溶接プロセスを加速し,ラインの高流量 (50~80ユニット/時間) に寄与する.

4表面処理

溶接後,鉄筋ラックは耐久性と美学性を高めるための自動表面処理を受けます.

デブーリング&ポーリング: ロボットブラシは鋭い縁と溶接のスプレーを除去し,スムーズで安全な仕上げを保証します.

コーティング 適用: 製品の要求に応じて,ラックは防腐コーティング,耐熱塗料 (商用モデル用) または装飾仕上げで噴霧されます.固化 炉 で 乾燥 し て 粘着 と 耐久 性 を 確保 する.

5. 組み立てと装着

この段階では,プリファブリックな部品 (ヒンジ,防滑パッド,または調整可能なノブなど) が溶接フレームに自動的に組み立てられます.ビジョンガイドロボットは正確なアライナメントを保証します.トルク制御スクリュードライバーは,使用中に松散するのを防ぐために固定装置を固定します.折りたたみ可能なモデルでは,このステップには,スムーズな折りたたみと展開を確保するためにヒンジメカニズムの校正が含まれます.

6品質検査とパッケージング

最終段階は,複数の点の品質チェックです.

尺寸確認: レーザーセンサーは設計仕様の遵守を保証するために主要な尺寸を測定します.

溶接の整合性試験: 超音波スキャンは溶接に隠された欠陥を検出し,構造強さを保証します.

機能試験:自動化システムで折りたたみ可能なメカニズム,負荷承受能力,表面仕上げ耐久性をテストする.

承認されたラックは,自動で包装ステーションに移され,包装,ラベル付け,運送に準備され,エンドツーエンドの製造プロセスを完了します.

わかったわかった

製品の特徴:

わかった自動化,精度,精密度,効率を活用して 産業の様々な製造ニーズに対応するように設計されています運用の卓越性を高めるための柔軟性以下は,その主要な応用シナリオです.わかった

家庭用品の生産者にとって この生産ラインは日常用家用アイロンラック標準サイズ (60cm×40cm~100cm×60cm) のラックを効率的に製造し,折りたたむデザイン,防滑表面,軽量アルミまたはステンレス鋼構造などの機能があります. The line’s quick changeover capability allows seamless switching between models—whether producing basic single-layer racks for small apartments or multi-functional racks with built-in garment hangers for family use高速生産 (50~80台/時間) で,製造業者は小売や電子商取引の注文量を容易に拡大することができます.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!